Datasheet download

Datasheet download

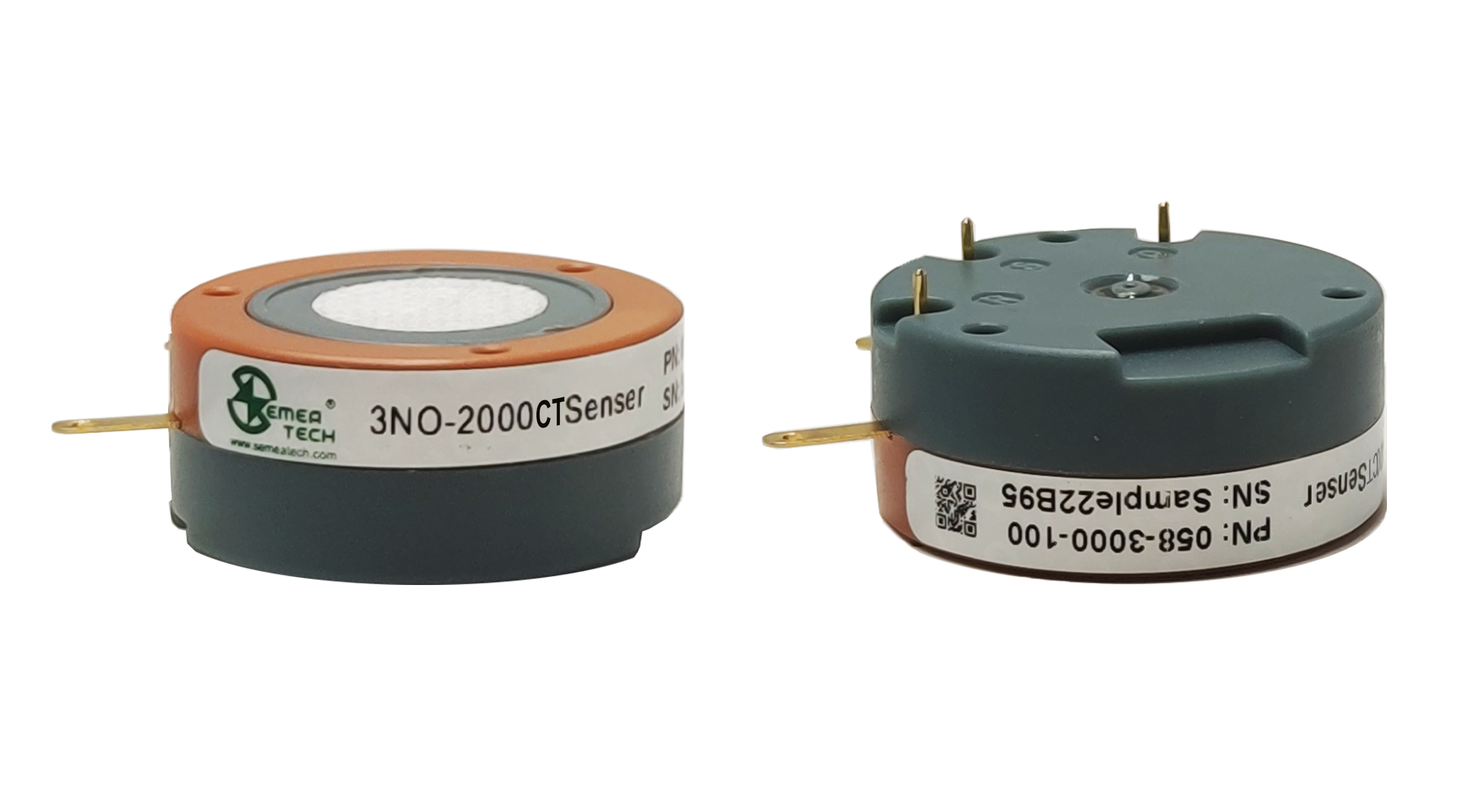

This Nitric Oxide (NO) gas sensor is designed as a replacement for a discontinued 3-series NO sensor produced by a major brand for monitoring and analysis of stack emissions or equivalent NO concentrations under harsh environmental conditions.

| Nominal Range | 0 ~ 2,000 ppm |

| Maximum Overload | 5,000 ppm |

| Sensitivity (20℃) | 0.10 ± 0.02 μA/ppm |

| Response Time (T90) | ≤ 25 s |

| Zero Signal (20℃) | 0 ~ +12 ppm |

| Baseline Shift (-20℃ ~ 50℃) | < 30 ppm |

| Resolution | 1 ppm |

| Linearity | Linear up to 2,000 ppm |

| Bias Voltage | +300 mV |

| Temperature Range | -20℃ ~ 50℃ |

| Pressure Range | 1 ± 0.1 atm |

| Humidity Range | 15% ~ 90%RH non-condensing |

| Long Time Output Drift | < 2% signal/month |

| Recommended Storage Temp | 10℃ ~ 30℃ |

| Expected Operating Life | 3 years in clean air |

| Storage Life | 6 months in original packaging |

| Warranty | 12 months |

| Max. Current at 5,000ppm NO | < 1 mA |

| Max. O/C Voltage | 1.3 V |

| Max. S/C Current | < 1.0 A |

| Housing Material | ABS |

| Weight (Nominal) | 23 g |

| Orientation | None |

Output signals from the sensor pins are different. Inappropriate use of the pins in product design will affect the sensor functionality. Exposure to high concentrations of solvent vapors should be avoided under any condition. Mechanical overstress may cause deformation or cracks of the plastic enclosure of the sensor. If the sensor is used in extreme environmental conditions, please contact us for more details.

| Gas | Concentration (ppm) | Output Signal (ppm NO equivalent) |

|---|---|---|

| Sulfur Dioxide | 100 | 0.2 |

| Nitrogen Dioxide | 90 | 0.5 |

| Carbon Monoxide | 500 | -0.2 |

| Hydrogen | 200 | 0.2 |

| Hydrogen Chloride | 100 | -0.5 |

| Hydrogen Sulfide | 200 | 0.4 |

| Ethylene | 200 | 0.4 |

Note: The cross sensitivities include but not limited to the above gases. It may also respond to other gases. The data in the table above may vary from different batches of sensors and the changes of test environment. Calibration using the gases that have the cross sensitivities to this sensor is not recommended.

This sensor is designed to be used in certain instruments for life critical applications. To ensure the sensor functions per its specifications inside the instrument, it is required to read the instrument user's guide carefully and comply with the calibration procedures by using certified target calibration gas before each use. Failure to do so may cause serious injury and fatality. Please do not open the sensor plastic enclosure because the electrolyte and other chemicals stored inside are harmful.

It is highly recommended for customers to validate the sensor performance using this document as a reference for their product designs or applications.